If you are a beginner at working with HTV and are facing trouble figuring it out, this article might be of some help to you. In this piece, we will cover some basic tips, tricks, and troubleshooting techniques to make working with HTV easy for you.

Troubleshooting Techniques

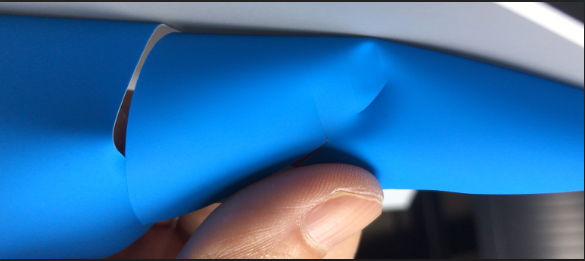

The HTV always has two sides. A shiny side, and a dull side. Therefore, vinyl has three layers- sheet covering the adhesive, vinyl, and carrier sheet. The shiny one is the carrier, and the dull one is the adhesive side. The dull side receives the cut when loaded into the cutter. Therefore, when loading the vinyl into the cutter, the shiny side goes down and the dull side goes up.

Test Cuts

We cannot emphasize enough on this one. Every vinyl has a different thickness. This also differs from manufacturer to manufacturer. Hence, this setting differs accordingly too. The pressure of the cutter has to be just right to make sure that the adhesive side and the vinyl are cut properly. But it shouldn’t be so that it cuts through the carrier sheet as well.

To achieve this, test cuts on a small piece of vinyl have to be done.

Weeding seems very difficult

If the cuts have been made properly, you wouldn’t face much trouble while reading your design. A weeding tool is very helpful in this step. But if it is difficult still, you can try and adjust the cuts settings or double cut the design. In short, TEST CUT!

Transfer Not adhering properly

If the instructions to press the vinyl onto the respective garments are followed properly, the vinyl will adhere 100%. These instructions always come along with the heat vinyl. But sometimes, too much or too little press time can result in the vinyl not sticking properly. So, it’s necessary to follow the instructions properly.

More Tips:

Some garments have a slight coating that makes them waterproof. This coating makes it difficult for adhesives from any heat transfer vinyl to penetrate the garment. To overcome this problem, This thin layer can be weakened by dampening the cloth with rubbing alcohol. Allow this damp spot to dry before applying the design. Washing and drying your garments prior to pressing your design is recommended.