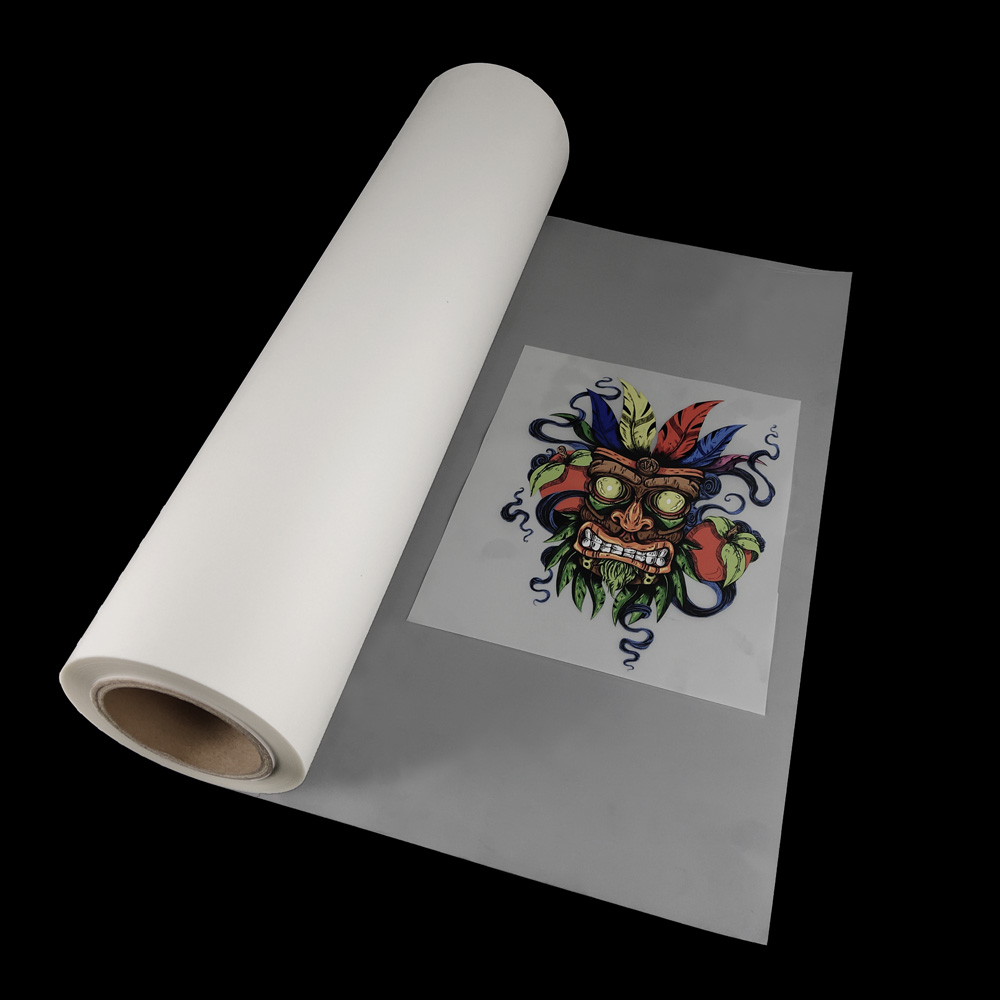

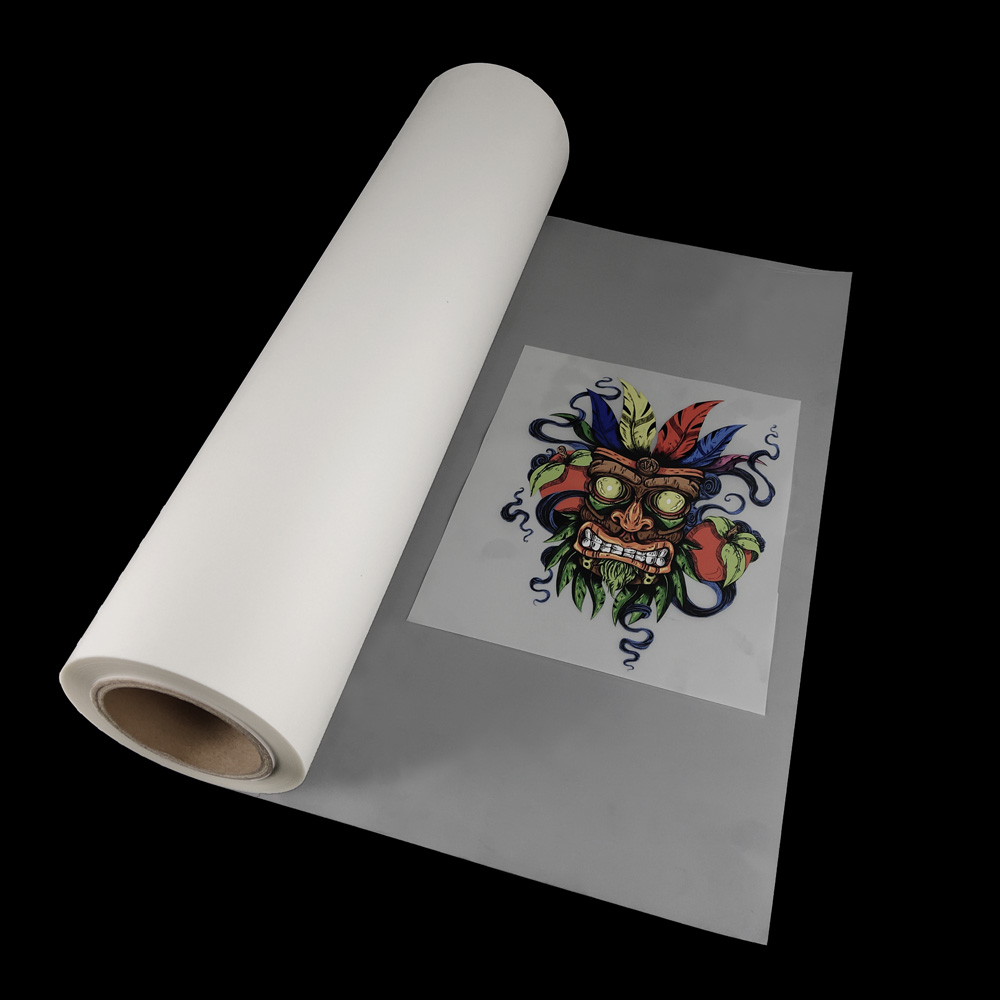

DTF film is a kind of hot stamping printing negative in the thermal transfer release film products. It belongs to the cold peel double site matte product and is used in pigment ink. In the aspect of direct-to-film printing, the product is mainly made of high-temperature-resistant polyester film (BOPET film), which has been precisely coated many times.

RECOMMENDED CONDITIONS HOW TO USE

![]()

![]()

Ink Time Temperature

Water pigment ink 10~15sec 150℃ (302℉)

![]()

Pressure Peel type Washing

32~36psi Cool peel Machine / hand

Product Features:

▶ Width: 30cm, 33cm, 60cm, 120cm or other customized width

▶ Length: 100m or other customized lengths

▶ Soft touch, good elasticity, and good washing fastness.

▶ Perfect for small and big designs.

▶ It is eco-friendly, there is no discomfort in contact with the skin, and no damage to the skin.

▶ It is suitable for cotton, poly, cotton-poly blend, textile, and leather.

Material | PET |

Thickness | 75UM + 3UM |

Finish | Double site matte |

Peel | Warm & Cold Peel |

Transfer Temp | 150℃ – 160℃ / 302’F – 320’F |

Transfer | Time 8-15S |

Transfer Pressure | 0.3-0.5MPa |

MOQ | 1 ROLL |

Precautions:

● It is strictly forbidden to collide with sharp objects. When the vinyl is not used up, please seal it and store it to prevent humidity and high temperature.

● The storage conditions are temperature -5 to 30 degrees, humidity 40-80%.

● It is normal for the surface to have a slight stickiness.

● Reasonably control the heat press temperature and time. If the temperature is too high or the time is too long, it is easy to cause discoloration or a decrease in elasticity.

● Not use strong corrosive detergents, not dry cleaning, and not use bleach.

● It is best to use water below 40 degrees, cold water is the best.